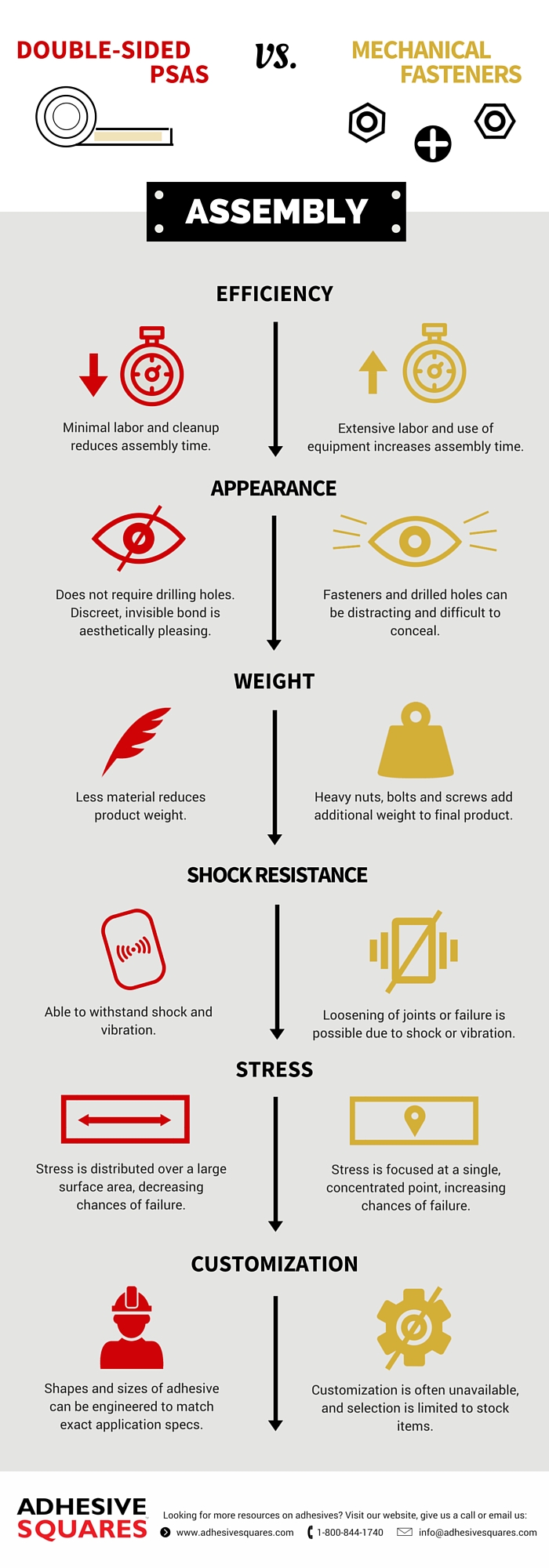

Efficient. Lightweight. Aesthetically pleasing. These are the demands that manufacturers’ products must meet. Traditionally, mechanical fasteners have been the primary means of joining materials together during assembly. But fasteners aren’t always capable of meeting these demands. Nuts, bolts and screws are increasingly being replaced by adhesives, specifically, pressure-sensitive, double-sided tape.

Double-sided tape benefits many assembly applications. Most notably, they can be quickly applied by hand, are not visible, and reduce the weight of the end product.

We compared pressure-sensitive tape to mechanical fasteners in 6 categories:

- Efficiency

- Appearance

- Weight

- Shock Resistance

- Stress

- Customization

Check out the infographic below to see how pressure sensitive adhesives compare to mechanical fasteners:

While double-sided tape may not be the solution for every assembly application, it’s clear that it offers many advantages, which increase production and product quality, and reduce failures. We strongly recommend working with an adhesive supplier to identify the best solution for your assembly application.

Our line of Adhesive Squares pressure-sensitive, double-sided tapes provides an excellent alternative to mechanical fasteners. For more information about Adhesive Squares, or to talk to someone about your specific application, contact our technical service team at 1-800-844-1740 or use the contact form below.