When it comes to applying adhesives, there is no such thing as a one-size-fits-all approach (if only it were that simple, right?). The proper amount of glue varies for every customer and application.

Liquid hot melts, for instance, require users to adjust equipment settings and parameters in order to ensure consistent bead width for adhesion. In order to get the best glue pattern, there are many factors to consider; these include bead profile, bead width and length, adhesive and substrate temperature, the right application speed and compression. There’s also the risk of applying too much adhesive, which may increase your material costs and cause adhesion failures.

The good news is that your adhesive process can be simplified. Double-sided tape is an easy-to-use alternative to traditional liquid hot melts. These pressure-sensitive adhesives are applied at room temperature, instantly bonding substrates without the use of any equipment.

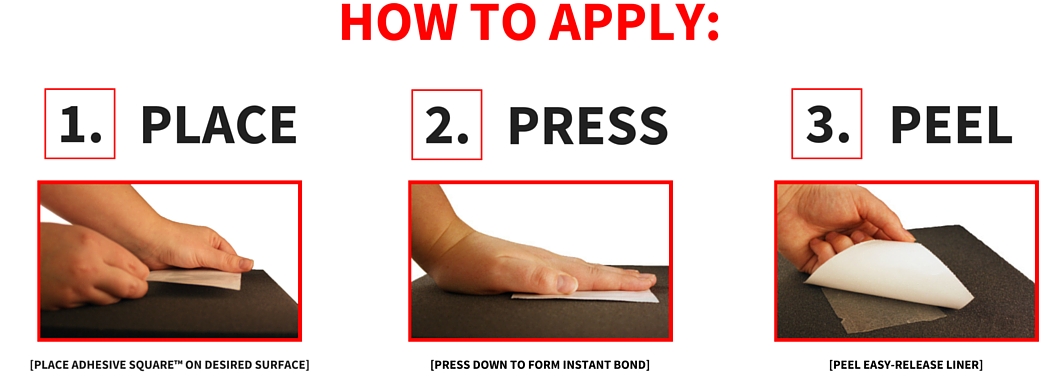

Unlike liquid hot melts, double-sided tape comes applied on a liner to provide the exact adhesive amount needed for your application. This decreases any issues that may stem from improper adhesive temperature, placement, compression, application speed or overconsumption. Simply place the adhesive onto your desired surface, press it down for easy release, and peel the liner to bond your substrates.

Double-sided tape comes in a variety of sizes, thicknesses and tack levels. You can choose from individual adhesive squares or strips, larger patches, or a continuous line. All formats provide the same level of adhesion you get with a liquid hot melt, minus the tweaking of hot melt machinery to get the desired glue pattern.

Double-sided tape is common in applications such as general packaging, point of purchase displays, bundling, marketing fulfillment and case and carton sealing. Whether this type of product will benefit you depends entirely on your specific application and process.

Some key factors you may review include production volume, safety concerns and customization needs. We always recommend working with your adhesive supplier to determine if a double-sided adhesive may be the best solution for your process.

Our line of Adhesive Squares double-sided tapes provides an easy-to-use alternative to traditional liquid hot melts. For more information, contact our technical service team at 1-800-844-1740 or use the contact form below. We’re available 24/7 to help you find the best solution to meet your application requirements.