Did you know that hot melt adhesives have been around for nearly 76 years? In 1940, Paul Cope, a chemical and packaging engineer at Proctor and Gamble, invented the hot melt as an improvement to water-based adhesives in packaging that were failing in humid climates.

Since the invention of the hot melt, we now have a wider selection to choose from: EVAs, PURs, metallocenes, polyamides and more. Then there are pressure sensitive, double-sided tapes. While the first group of liquid hot melts requires heat to activate, double-sided tape is applied at room temperature.

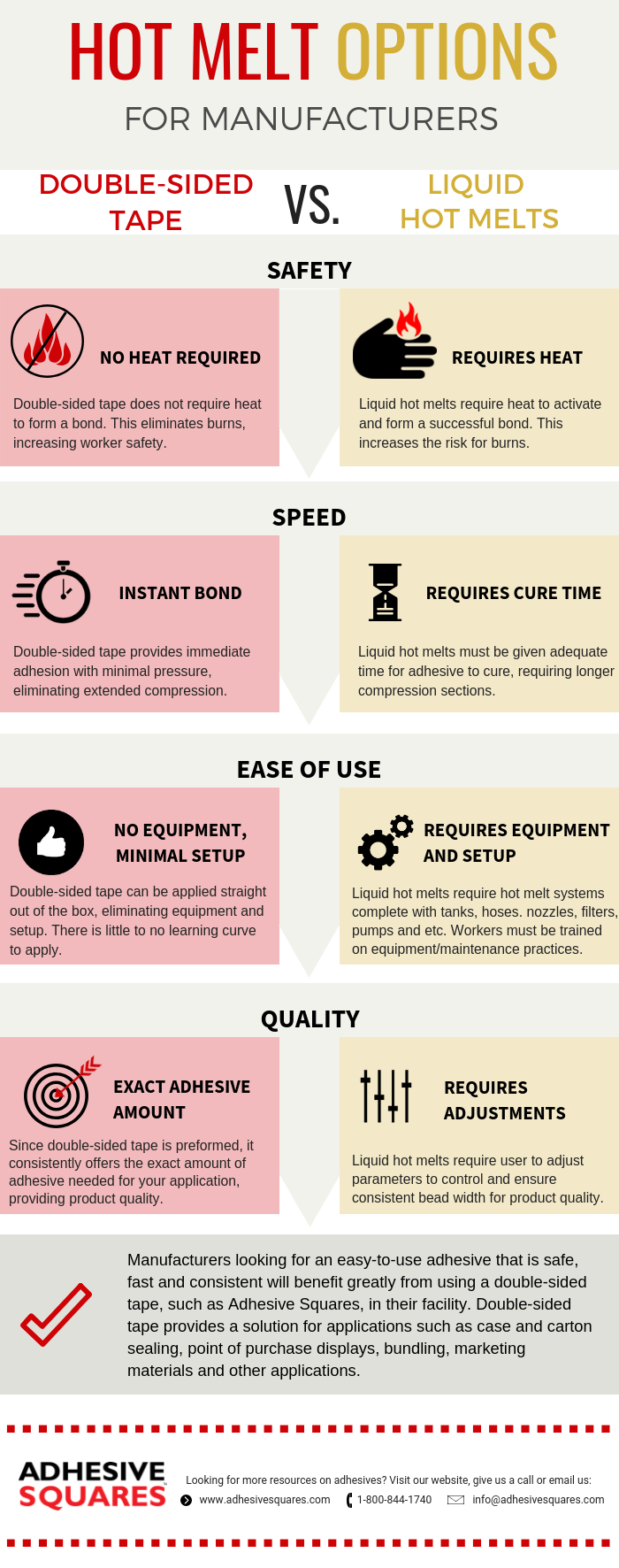

Heat aside; there are several key differences between double-sided tape and liquid hot melt adhesives. We compared the two in four major categories, which include:

- Safety

- Speed

- Ease of use

- Quality

Take a look at the infographic below to see how double-sided tape compares:

Many businesses integrating a hot melt to increase the efficiency of their process could benefit from considering a pressure-sensitive, double-sided tape. Some key factors you may review include production volume, safety concerns and customization needs. We always recommend working with your supplier to determine if a double-sided tape product would be the best option for your process.

Our line of Adhesive Squares double-sided tape provides a valuable alternative to liquid hot melts. For more information about Adhesive Squares or to request a product sample, contact our technical service team at 1-800-844-1740 or use the contact form below. We’re available 24/7 to discuss your specific application in more detail.