It’s no easy feat selecting the right adhesive. Do you go with a water-based or a hot melt adhesive? You might be recommended a hot melt pressure-sensitive adhesive. But what’s the difference between a rubber-based pressure sensitive adhesive versus acrylic? And which format – single coated or double coated – is best? The answer all depends on your application.

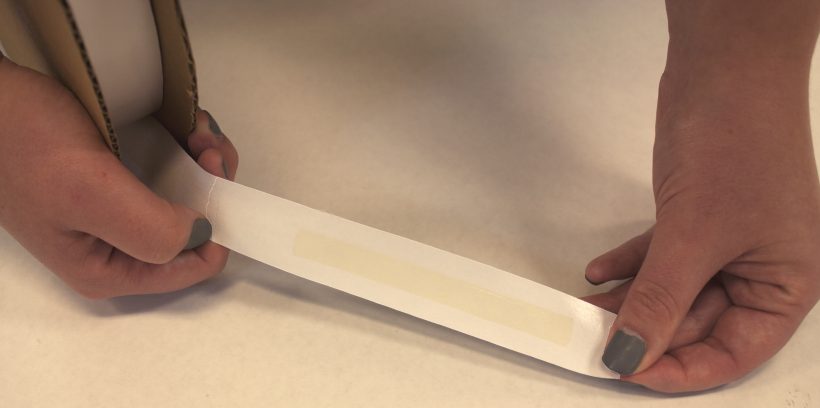

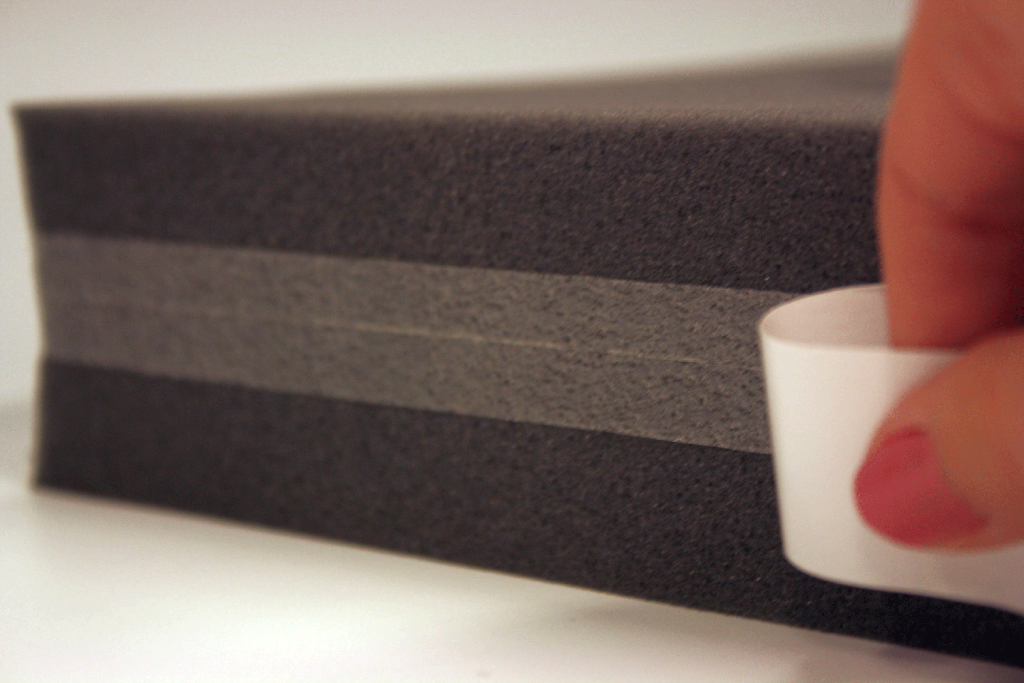

First of all, what is a PSA? A pressure sensitive adhesive is a hot melt that is tacky at room temperature and requires pressure in order to bond substrates. Despite being a hot melt, no heat is involved in the application process making it safer than traditional liquid hot melts. The adhesive usually comes on a roll and hand application is one of the easiest ways to apply it.

There are three main chemistries when it comes to PSAs:

- Silicone-based: Silicone-based PSAs are generally known for their higher temperature resistance. Although they have low initial tack strength, this increases over time and is able to withstand continuous temperatures of 400°F. You might see this type of PSA being used in demanding applications, such as those in aerospace or automotive industries.

- Acrylic-based: Acrylic-based PSAs are very durable and provide excellent temperature, UV and oxidation resistance. This makes them ideal for outdoor applications. Acrylics usually do not bond well to low-energy surfaces, such as polyethylene and polypropylene. Overall, they do not have adhesion as aggressive as rubber-based adhesives.

- Rubber-based: Rubber-based PSAs are aggressive in nature and are known for their versatility in bonding a variety of substrates. Unlike acrylics, rubber PSAs adhere well to several low-energy surfaces, including polyethylene and polypropylene. Although they are not ideal for high temperatures, rubber PSAs are an excellent general-purpose adhesive.

In addition to their chemistries, pressure-sensitive adhesives are available in three different formats:

- Single-sided: An adhesive is applied to only one side of the backing. The backing may be constructed of paper, film, foil or nonwoven material. Examples of single-sided PSAs include masking, electrical, medical and carton sealing tapes.

- Double-sided: An adhesive is applied to both sides of the backing. Typically, the release liners are paper with adhesive coated on both sides of the paper. The release liners are commonly paper and silicone is coated on both sides for easy release. Mounting and medical tapes are examples of double-sided tapes.

- Reinforced: Adding on to the backing and adhesive, these PSAs include woven or knitted cloth reinforcement. Typical backings include polyethylene and polyester films. Duct tape is an example of a reinforced tape.

We always recommend you work with an adhesive supplier to select the best adhesive for your application. Our line of Adhesive Squares™ double-sided PSAs provides an easy-to-use solution for your tape needs. Want to discuss your application with us? Give our technical service team a call at 1-800-844-1740 or use the contact form below.